Moulded Raw edge cogged Belts

Toothed Belt or Moulded Raw Edge Cogged Belt is a V-Belt with moulded teeth on its inner surface.Toothed Belts offer more flexibility compared to the Wrap construction Belts and the tooth profile allows the accumulation of air pockets into it, which acts as heat absorber and prevents the temperature of the drive to enhance, during operation.

In the case of toothed Belts the teeth which run perpendicular to the Belt length reduces the bending stress over the Belt, they run cooler, lasts longer, and have a substantial operational efficiency compared to Wrap construction Belts. Toothed Belts can be used over the same pulleys as equivalently rated Wrap construction Belt Pulley.Toothed Belts are used in a wide array of mechanical devices, where high power transmission is desired.

REENOLDS offers a wide range of toothed Belts of various profiles, such as; ZX, AX, BX, CX, DX; Classical sections. XPZ, XPA, XPB, XPC, Wedge Belt sections and 3VX, 5VX, 8VX; Narrow sections.

Besides the standard sections of toothed Belts, REENOLDS also offers the High-power, maintenance-free Muscle series of Belts, which delivers high-power and are maintenance-free, offering compact drives.

Features

- Higher power transmission capacity than wrapped Belts

- Special cog design for enhanced flexibility and heat dissipation rate

- Suitable for drives using smaller diameter pulleys and high RPM

- Anti-static, oil & heat resistant

- Maximum Belt linear speed (Classical section: up to 30 m/Sec, Wedge: up to 42 m/Sec, Narrow: up to 45 m/Sec)

- Temperature range: -25°C to +100°C

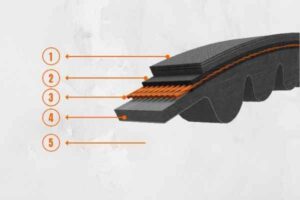

Constructional Details

- Special fabric layer

- Cushion rubber compound

- Specially treated & stabilized polyester cord

- Fiber-filled base compound

- Moulded cogs for better flexibility

Product Range

| Classical Section | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Section | Top Width (mm) | Thickness (mm) | Angle (Degree) | Min. Pulley Dia. (mm) | Manufacturing Range | Belt Length Factor (mm) | Length Desg. | |||

| Min. (inch / mm) | Max. (inch / mm) | Lp to La | Li to Lp | Li to La | ||||||

| ZX | 10.0 | 6.0 | 36 | 40.0 | 21.5″ | 100″ | 16 | 22 | 38 | Li |

| AX | 13.0 | 8.0 | 36 | 63.0 | 21.5″ | 100″ | 14 | 36 | 50 | Li |

| BX | 17.0 | 11.0 | 36 | 90.0 | 21.5″ | 100″ | 26 | 43 | 69 | Li |

| CX | 22.0 | 14.0 | 36 | 140.0 | 23.5″ | 100″ | 32 | 56 | 88 | Li |

| DX | 32.0 | 19.0 | 38 | 280.0 | 40.0″ | 100″ | 40 | 79 | 119 | Li |

| Wedge Section | ||||||||||

| XPZ | 10.0 | 8.0 | 36 | 56.0 | 550mm | 2500mm | 13 | 37 | 50 | Lp |

| XPA | 13.0 | 10.0 | 36 | 71.0 | 550mm | 2500mm | 18 | 45 | 63 | Lp |

| XPB | 16.3 | 14.0 | 36 | 112.0 | 550mm | 2500mm | 28 | 60 | 88 | Lp |

| XPC | 22.0 | 18.0 | 38 | 180.0 | 600mm | 2500mm | 30 | 83 | 113 | Lp |

| Narrow Section | ||||||||||

| 3VX | 9.7 | 8.0 | 38 | 56.0 | 21.5″ | 100″ | 13 | 37 | 50 | La |

| 5VX | 15.8 | 14.0 | 38 | 112.0 | 21.5″ | 100″ | 25 | 60 | 85 | La |

| 8VX | 25.4 | 23.0 | 38 | 254.0 | 90″ | 100″ | 53 | 92 | 145 | La |

Note

- Intermediate sizes are available upon request

- Aramid cord construction Belts are available upon request

Reference Standards

IS 2494, BS 3790, ISO 4184, RMA IP 22, RMA IP 23

Applications

Compressors, pumps, fans, vacuum pumps, blowers, generators, heat exchanger, industrial drives, etc

Product Label